Metallisierungen mit dem Lichtbogen (Zink oder Alu-TSA)

Beschichtungssysteme, die eine Verzinkung mit zusätzlichen Farbschichten kombinieren, bieten einen besonders wirksamen Korrosionsschutz. Voraussetzung für die volle Wirksamkeit des Duplexsystems ist eine gute Haftung der Beschichtung auf der Zinkschicht. Diese optimale Oberfläche können wir durch Lichtbogenspritzen erzeugen.

Selbst große Bauwerke und schwere Gegenstände, die in einer Verzinkungsanlage nicht behandelt werden können, werden durch Lichtbogenspritzen verzinkt. Ein Verziehen der Werkstücke, wie es bei der Feuerverzinkung der Fall ist, entfällt.

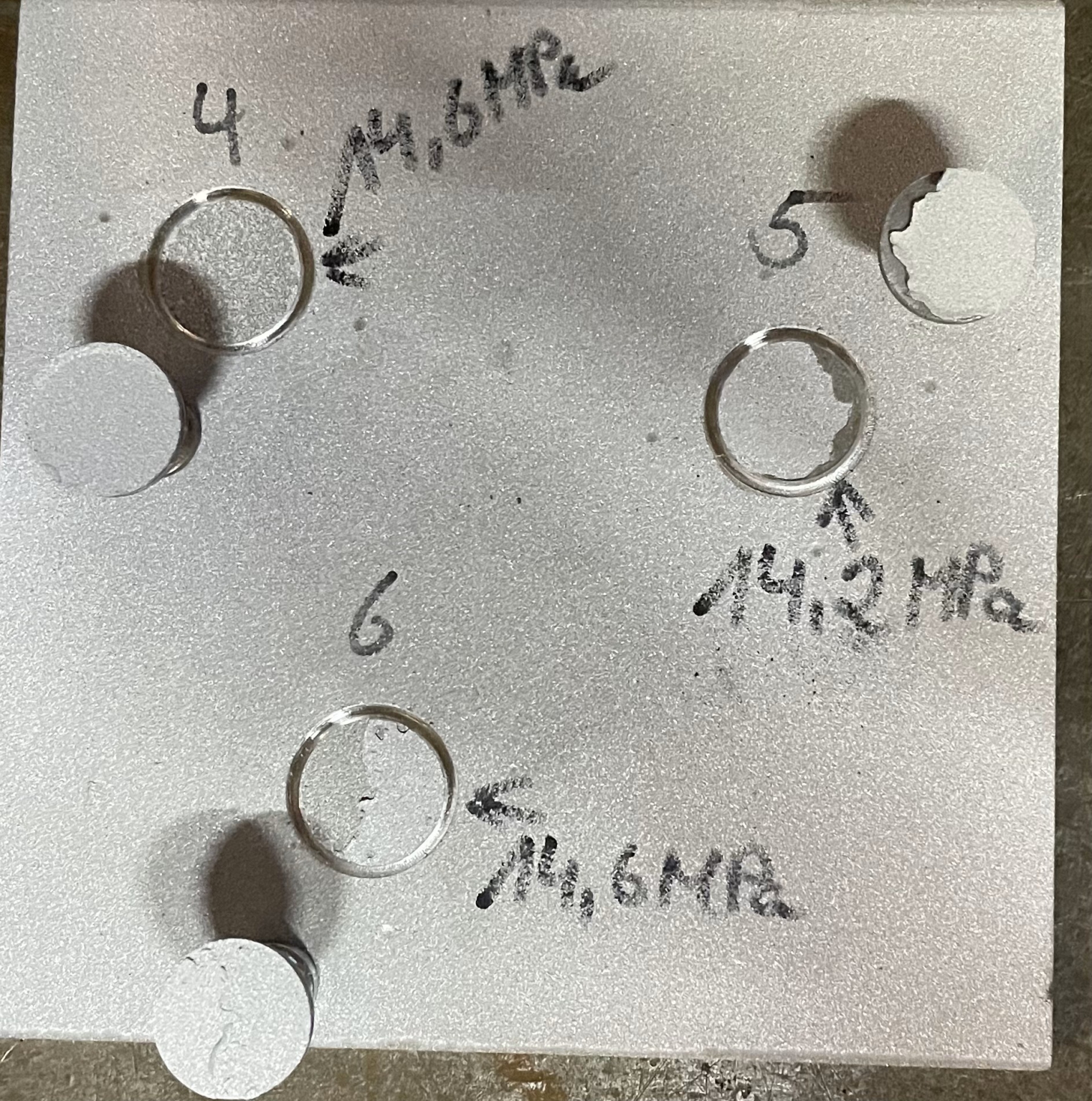

Beschichtungen, die im Lichtbogenspritzverfahren aufgetragen werden, zeichnen sich durch eine hervorragende Haftung aus, die die des Flammspritzens übertrifft. Die Spritzpartikel verschmelzen mit dem Grundmaterial. Die Farbe der aufgespritzten Beschichtungen ist vom Grundmaterial kaum zu unterscheiden.

Lichtbogengespritzte Beschichtungen weisen eine etwa dreimal höhere Zugfestigkeit und eine geringere Schrumpfspannung auf als flammgespritzte Beschichtungen. Metallgespritzte Beschichtungen sind mikroporös, was erhebliche Vorteile für Gleitlager und Dichtringe bietet. Unabhängig vom Grundwerkstoff können alle Werkstoffe metallisiert werden, z. B. Eisen-/Nichteisenlegierungen auf Gusseisen.

Beim Lichtbogenspritzen werden zwei drahtförmige, elektrisch leitfähige Spritzmaterialien kontinuierlich in einem bestimmten Winkel aufeinander zugeführt. Nach der Zündung brennt zwischen den Spritzdrähten (Elektroden) ein Lichtbogen, der das Spritzmaterial schmilzt. Ein kräftiger Druckluftstrom zerstäubt das geschmolzene Material und beschleunigt die Spritzpartikel auf die Werkstückoberfläche. Verfahrensbedingt können ausschließlich metallisch leitfähige, drahtförmige Materialien verarbeitet werden.

In der Offshore-Ölindustrie wird häufig eine Aluminierung (TSA = Thermal Spray Aluminium) eingesetzt, die anschließend mit einer Versiegelung (nachträgliche Beschichtung) versehen wird. Die Arbeiten werden durch einen qualifizierten European Metalsprayer ausgeführt (DIN EN ISO 14918).

Seiten

TAGS

LEISTUNGEN

Strahlentrostung

Metallspritzen (TSA)

Korrosionsschutz

Pulverbeschichtung

Kontakt

Karl Röttgers GmbH

Deverhafen 19

26871 |

Telefon +49 4961 9499 0

eMail info@roettgers.de